MENU

Starting a Business

- Best Small Business Loans

- Best Business Internet Service

- Best Online Payroll Service

- Best Business Phone Systems

Our Top Picks

- OnPay Payroll Review

- ADP Payroll Review

- Ooma Office Review

- RingCentral Review

Our In-Depth Reviews

Finance

- Best Accounting Software

- Best Merchant Services Providers

- Best Credit Card Processors

- Best Mobile Credit Card Processors

Our Top Picks

- Clover Review

- Merchant One Review

- QuickBooks Online Review

- Xero Accounting Review

Our In-Depth Reviews

- Accounting

- Finances

- Financial Solutions

- Funding

Explore More

Human Resources

- Best Human Resources Outsourcing Services

- Best Time and Attendance Software

- Best PEO Services

- Best Business Employee Retirement Plans

Our Top Picks

- Bambee Review

- Rippling HR Software Review

- TriNet Review

- Gusto Payroll Review

Our In-Depth Reviews

- Employees

- HR Solutions

- Hiring

- Managing

Explore More

Marketing and Sales

- Best Text Message Marketing Services

- Best CRM Software

- Best Email Marketing Services

- Best Website Builders

Our Top Picks

- Textedly Review

- Salesforce Review

- EZ Texting Review

- Textline Review

Our In-Depth Reviews

Technology

- Best GPS Fleet Management Software

- Best POS Systems

- Best Employee Monitoring Software

- Best Document Management Software

Our Top Picks

- Verizon Connect Fleet GPS Review

- Zoom Review

- Samsara Review

- Zoho CRM Review

Our In-Depth Reviews

Business Basics

- 4 Simple Steps to Valuing Your Small Business

- How to Write a Business Growth Plan

- 12 Business Skills You Need to Master

- How to Start a One-Person Business

Our Top Picks

How to Easily Implement a 5S Program for Your Business

Table of Contents

If your business operations sometimes (or always) feel chaotic and inefficient, your company may benefit from implementing a 5S program. This organizing and streamlining process can be used in any business but is considered essential in manufacturing.

Regardless of your industry, you can benefit from this way of thinking and operating to make your business more organized and efficient. A 5S program gives employees the agency to create efficiencies and continuous improvement. When each employee is empowered and motivated by these goals, the entire organization benefits.

What is a 5S program?

5S is a five-step methodology created in Japan. It’s the foundation of the total productive maintenance system for manufacturers, where operators are responsible for maintaining their equipment to reduce breakdowns, stoppages and defects. 5S is also an integral part of the lean methodology movement in manufacturing.

5S methodology includes the following tenets to create a more organized and efficient workplace:

- Sort: Separate necessary things and get rid of anything that isn’t needed. If items are needed in another work area, move them to the correct place.

- Straighten: Take the remaining things and organize them. Use labeling, containers, color coding or anything else that makes sense for the items you are straightening.

- Shine: Clean and inspect the work area. If something’s broken or is causing a leak, identify the issue and fix it.

- Standardize: Create processes and standards for the first three steps. Keep it simple so it’s easy to sustain. Checklists are helpful.

- Sustain: Consistently apply the standards to maintain and improve operations.

When all employees are engaged in this process, the organization eliminates waste and reduces resource burn and inefficiencies. A 5S program can change your workplace culture so each employee is focused on – and takes pride in – quality, productivity, workplace safety and efficiency.

You can apply 5S to digital workspaces with file management best practices, like organizing computer files into logical folders.

How do you implement a 5S program?

Any business can adopt and implement a 5S program. Here’s how to get started.

1. Get familiar with lean philosophy before starting a 5S program.

Before starting a 5S implementation, immerse yourself in lean methodology and philosophy. Organizations that experience 5S success use lean tools like 5S audits and track key performance indicators (KPIs) to help gauge success (more on this below). Additionally, most stakeholders intend to continue with a lean philosophy after conducting a 5S program. If you can’t successfully implement 5S, you don’t have a chance of implementing lean.

The book Lean Thinking: Banish Waste and Create Wealth in Your Corporation, by James Womack and Daniel T. Jones, is a must-read for anyone starting a lean journey. Additionally, The 5S Pocket Guide, by James Peterson and Roland Smith, discusses everything you need to know about 5S programs in a condensed form.

Reading these books is the first step toward efficiently implementing a 5S program for your organization.

2. Introduce the 5S program and train employees.

Hold a meeting with your employees about the new 5S program and discuss the following:

- Inform them that a 5S program can make their jobs easier and more efficient.

- Get their input about the best ways to organize their work areas.

- Ask them about the tools they use in their jobs (this includes computer files) so you can make it easy and quick to access them.

- Give them examples of what an organized and clean work area looks like.

- Have departments with standardized methods meet together with their managers to create bespoke systems.

3. Conduct 5S audits with unique KPIs to ensure continuous improvement.

Conduct audits to keep people motivated and continuously improving during the 5S process. Every business will have unique KPIs to measure each 5S element’s improvements during audits.

To conduct a 5S audit:

- Create a simple Excel spreadsheet with five elements the company must work on based on each 5S category: sort, straighten, shine, standardize and sustain.

- For each 5S category, create unique KPIs to measure – what to look for during an audit.

- Give each KPI a score of 1 to 5, depending on the improvements witnessed. All lines have a maximum score of 5.

- Find the category’s average score.

Here’s an example of an audit with KPIs for straighten. In this example, two areas experienced low scores, while others showed more improvement. These results are part of the continuous improvement effort that is the backbone of lean methodology.

Straighten: Everything has a place, and everything in its place

What to look for | Score (maximum of 5; take off a point for every nonconformance) | Average |

|---|---|---|

Workplace tools in shadow boards after use | 3 | 4 |

All nonessential items out of the area | 5 | |

Hard-copy documents in workstation holders | 2 | |

Pallet jacks returned to the correct area | 5 | |

Job performed at correct workplace station | 5 |

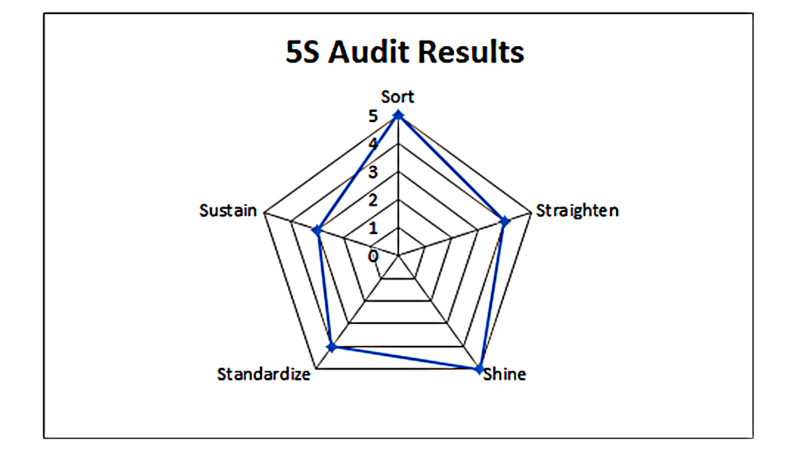

You can feed results from the 5S audit forms to data fields in an Excel 5S radar chart. A 5S radar chart is a robust visualization tool that can lead to root-cause analysis troubleshooting and strategies to help alleviate any issues and prevent their reoccurrence. Once you get problems under control after monitoring, you can change audit elements to address new housekeeping issues.

Image courtesy of Holly Chavez

Have various leaders and managers conduct audits because new perspectives keep things fresh.

What are the benefits of a 5S program?

Implementing a 5S program has many benefits that can be felt throughout the organization. Here are some of the most crucial benefits.

1. A 5S program eliminates waste.

A 5S program can reduce operational costs while eliminating waste.

Let’s say someone in your office needs paper to print a long proposal. They take a ream of paper from the storage area, use what they need and leave the excess paper on their desk. Another employee has printing needs, but the printer is out of paper. They go to the storage area for more, but there is none. They can’t print what they need until the company orders more paper.

This expenditure is unnecessary; a 5S program would have prevented it. The first employee would have returned the ream of paper to the storage area, and the second employee could’ve accessed it immediately.

2. A 5S program prevents equipment breakdowns.

A 5S program trains employees to create a process where they clean and inspect the equipment they use. They become better able to spot problems before they become severe.

For example, say a manufacturing employee is cleaning a machine. They notice a puddle of oil on the floor and wipe it up. They investigate further, following the puddle to its source and noticing a small crack that may be causing a leak. They report the issue to management or the department in charge of repairs, preventing a small problem from getting worse and ultimately becoming a safety hazard or stopping production altogether.

3. A 5S program reduces work site accidents.

A 5S program can reduce accidents and help keep your business safe. For example, accidents are not uncommon in an environment that uses tools, such as a construction site. Workers may leave tools lying around on the ground where others can trip on them. They may also leave raw materials in a disorganized state, making it more likely that people will trip. The materials can also fall, potentially injuring workers and making the materials unusable, causing enormous repercussions for the construction business.

A 5S program helps workers get into the habit of keeping a clean and organized work area, creating a safer environment with fewer workers’ compensation claims and other issues.

OSHA construction site standards aim to reduce the likelihood of serious injuries caused by falling, being struck by an object, electrocution, and being caught in or between objects.

4. A 5S program improves efficiency and productivity.

A 5S program streamlines operations, improving productivity and efficiency. When employees always know precisely where daily-use items belong, they can get to work immediately without searching for what they need. They won’t have to dig through clutter when things are organized with 5S. These efficiency standards also make it easier for new hires to become productive more quickly.

5. A 5S program reduces employee frustration and stress.

Employees appreciate the organization a 5S program engenders. Everything they need is easily accessible, so there’s no frustration trying to find things. Each employee is responsible for cleaning and organizing their workspace and can often create an environment that works best for them and the organization.

Employees become more confident when interacting with co-workers because everything is organized logically and transparently. There are fewer silos and more interdepartmental communication.

6. A 5S program costs little to implement.

A 5S program won’t cost your organization much to create and implement. All you need is an investment in employee training and periodic 5S audits.

Gather anonymous employee feedback to gauge how well the implementation is going and pinpoint areas where more guidance is needed.

5S program best practices

Consider the following advice for kickstarting your 5S workplace organization:

- Introduce the 5S program with positivity. 5S is considered a transformational tool. For best results, don’t be heavy-handed with your implementation. You’re asking people to go beyond their typical job scope, so positivity and pleasant circumstances will go a long way toward your eventual success.

- Inform all departments of the 5S plan. Everyone should understand what’s happening and be on board with the new program. To begin, hold an ice-breaking meeting with all affected departments. Give teams an overview of 5S core tenets and how you plan to implement the program. Sharing 5S benefits is crucial for getting everyone’s buy-in. Ideally, provide a strategic timetable or completion date. Let everyone know when you’ve completed each step, and keep everyone informed of your progress.

- Lead by example during the 5S process. Leading by example is crucial for 5S success. Get in the trenches with your team, and work through the process with them. Continued improvement will motivate everyone. Show appreciation for the physical workload the first three S’s entail. Take before-and-after pictures to provide convincing proof for workers and visitors that the program is working. After you’ve made some initial gains, these pictures will provide motivation to continue 5S endeavors.

Holly Chavez contributed to this article.